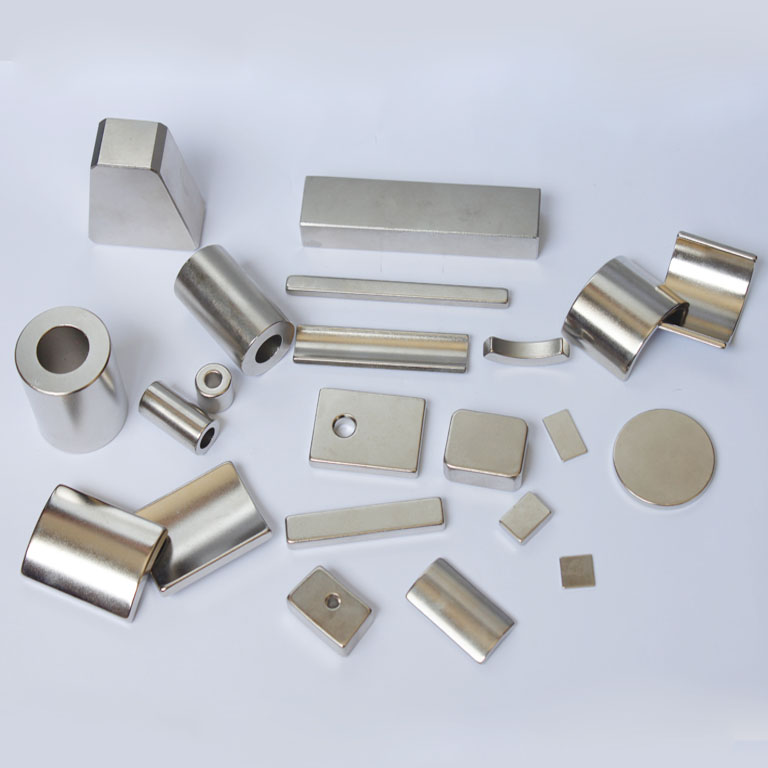

Tube magnets (also called Magnetic tube, Magnetic rod) are consist of several pieces of neodymium magnets assembled into a steel tube, while Grid magnets (also called Magnetic grid, Grate magnets, Magnetic grate) are constructed by several tube magnets mounted in a sealed housing to be easily installed into a production line, the shape can be circular, square or other special shapes.

The tube and grid magnets are a simple and economical solution of magnetic separation, the magnetic strength is very strong from 2000Gs to maximum 12000Gs, they are used to pick out ferrous objects passing over their surface, the steel part is with good corrosion resistance and fine polished, and the standard working temperature is 80℃, while the maximum working temperature can reach 350℃ if required.

Types of Tube and Grid Magnets

Manufacturing method

The strong magnets will be put into steel tube, each 2 magnets are interleaved a certain distance and seal-welded on two ends, upon different industries where tube and grid magnets are used, different magnets will be used, Neodymium magnets are standard version, while SmCo, AlNiCo and ferrite magnets are also available. The steel tube is stainless steel, mainly SS304 while food quality SS316 steel is also offered, both are corrosion resistant and easy to clean.

The standard diameter of tube is 25mm, with standard lengths from 100mm to 600mm, other common diameters like 16mm, 20mm, 32mm, 40mm, 50mm, 76mm, 100mm are available too, while for the square bars, the common sizes are 19 x 19mm, 25 x 25mm. The two ends can be with various plug ends like plain tight sealed, threaded hole, threaded rod, nail head and eye nuts.

Applications

Tube and Grid magnets are extremely versatile and widely used in various industries like food processing, plastics, textile, medicines, sanitation, smelting, machinery, chemical and powder, they are installed at a certain place or several places of the production flows to remove unwanted ferrous objects, like nuts, screws, chips, nails, and other scraps, it can help protect the whole machine and facilities and ensure the quality of the goods.

中文

中文